TECHNOLOGY, INNOVATION AND SERVICE

EVOLVING

Success lies in having precisely those skills required at that moment. Henry Ford

SAMPLING

For Verona Lamiere, the sampling process is a fundamental step in ensuring product quality and compliance before starting mass production. Each sample is produced in close collaboration between the technical department, production and quality control under the strict coordination of the Project Manager, with the aim of verifying compliance with the customer’s specifications and optimising the processing parameters.

This activity allows us to promptly identify any critical issues, improve the efficiency of the production process and ensure reliable and timely order fulfilment. Sampling is a strategic tool for Verona Lamiere to consolidate customer confidence and ensure high standards from the initial operational phase.

The company has developed an organisation capable of operating not only using its technological systems but also the specific skills acquired over time by individual operators, using lean production logic and rigorous quality control systems.

01234567890

Laser 2D e 3D

01234567890

Punching

01234567890

Combinated

01234567890

Panel benders

01234567890

Folding

0123456789001234567890

Bending

01234567890

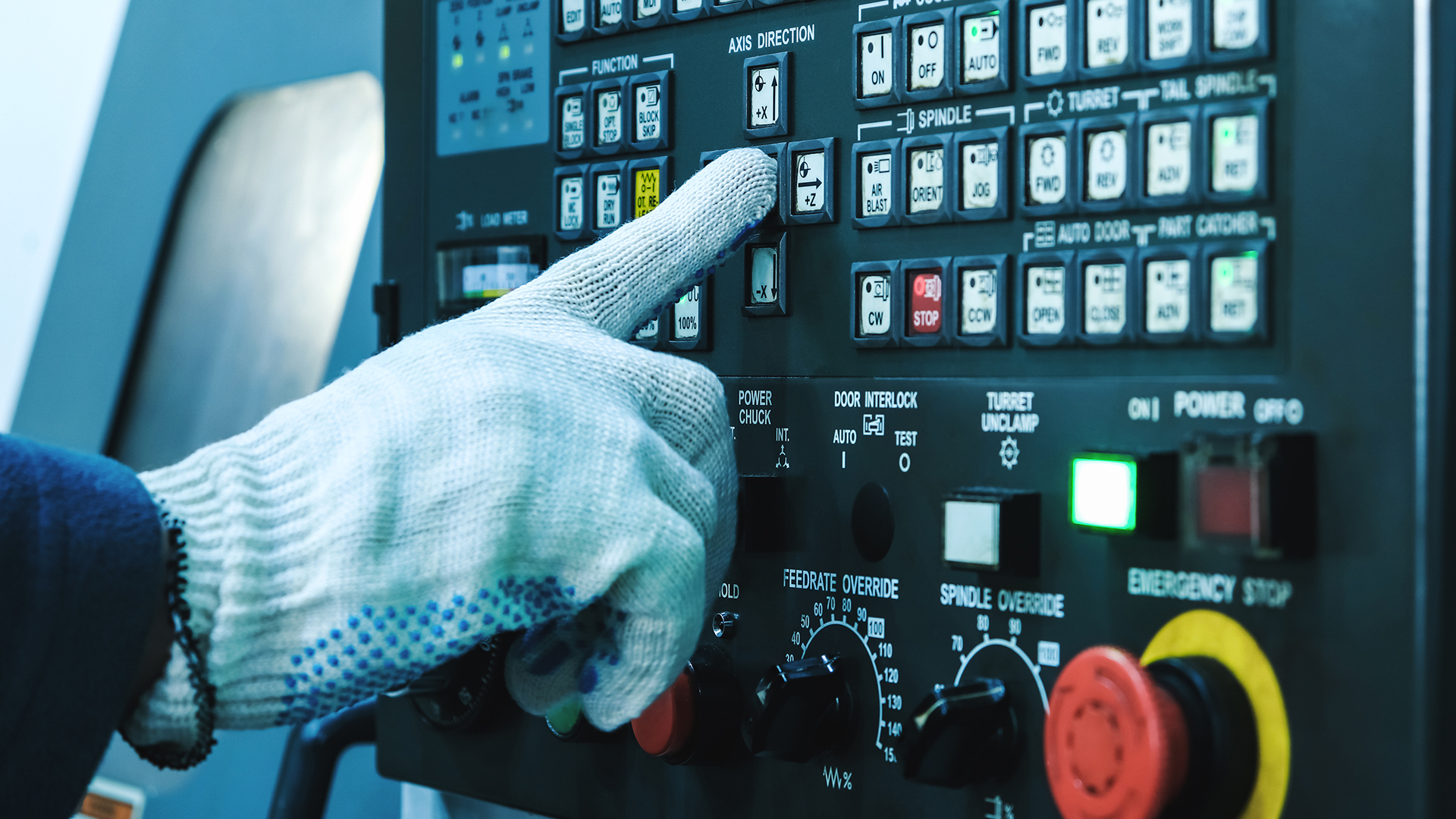

CNC

0123456789001234567890

Molding

0123456789001234567890

Carbon steel welding

01234567890

Robot carbon steel welding

0123456789001234567890

Stainless steel and aluminum welding

01234567890

Robot stainless steel and aluminum welding

0123456789001234567890

Spot welding and assembly

01234567890

Quality Control and Metrics

01234567890012345678900123456789001234567890mq

Large mechanical assembly area.

DESIGN

ANALYSIS

Customer support right from the design phase

Each sheet metal product is developed from an in-depth technical-economic study, essential to precisely define the bill of materials and identify the optimal production cycle. This preliminary stage guarantees efficiency, quality and cost sustainability in the subsequent production of sheet metal components.

This is followed by the creation of technical drawings and CAD/CAM programming, which are essential for starting sheet metal processing using high-precision CNC machinery. Key figures such as the Project Manager and Technical Leader are involved in this industrialisation phase, with the task of ensuring that the customer receives a sample that perfectly complies with the required technical specifications.

The entire sheet metal production cycle is managed using specialised software that supports both the scheduling and monitoring of order progress. To better address the growing technical and organisational complexity of the sector, the company constantly invests in staff training and the development of its internal skills, with the aim of offering increasingly high-performance solutions tailored to every need.

VERONA LAMIERE

PROCESSING

Various technologies to optimise the production process

Co-Design

Each product is preceded by a thorough technical-economic study carried out together with the customer, aimed at defining the bill of materials and identifying the most efficient production cycle.

Laser cutting

Laser cutting combines cutting-edge technology and specialised skills to ensure precise and reliable processing. Depending on the type of material chosen.

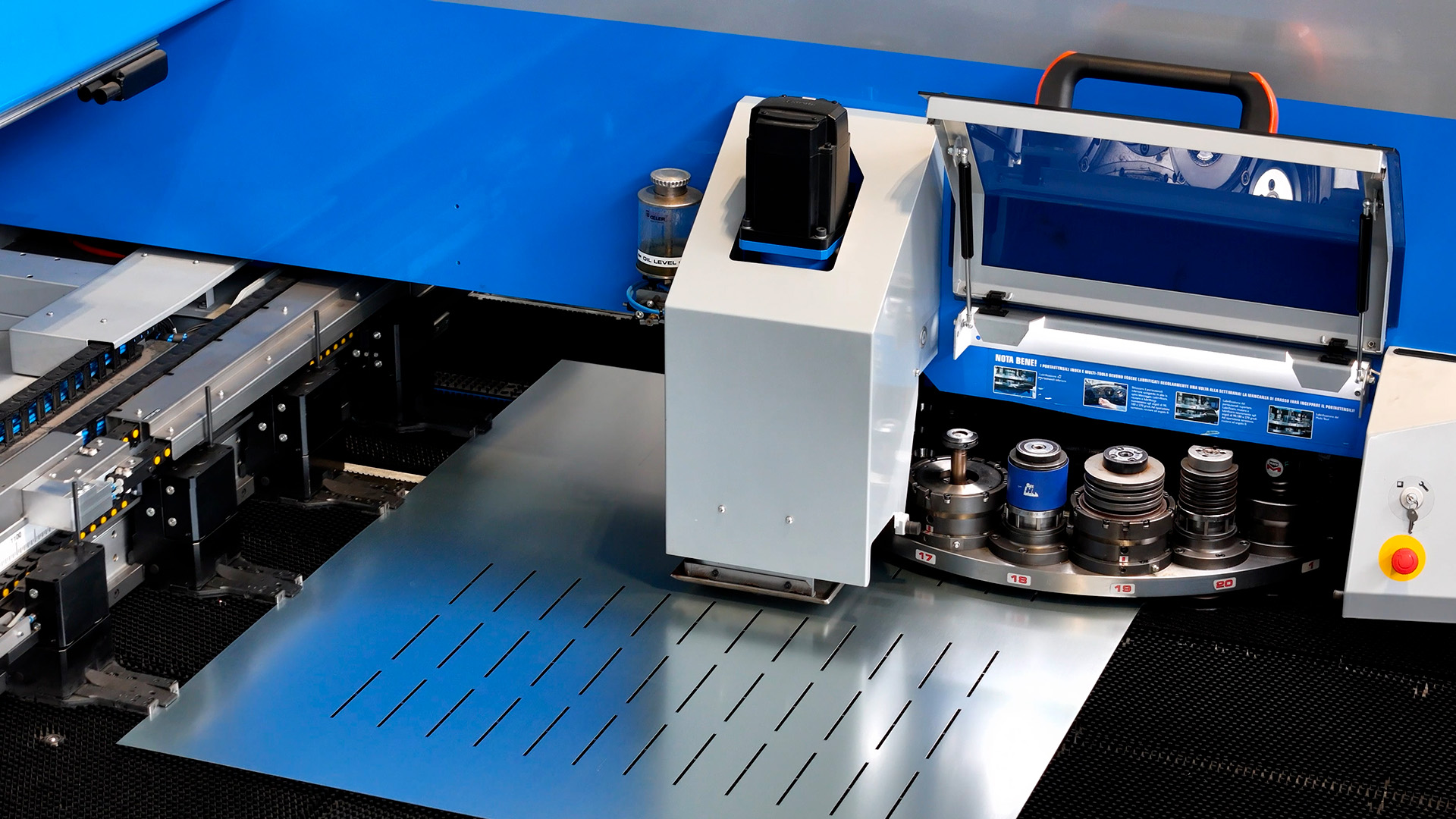

Punching

Punching and combined punching/laser systems for maximum speed and operational flexibility. Efficiency of various production requirements, maintaining high quality standards.

Folding+Robot

The folding department offers a wide range of processes, thanks to a highly diversified and cutting-edge fleet of machinery. Each machine is designed for efficiency, flexibility and precision.

Moulding

The moulding department focuses on high-volume production and components with deformations. The tooling shop and machining centres carry out removal processes and build the equipment necessary for production.

Assembly

Assembly is often the point at which the subcontractor moves from being a simple supplier of parts to a strategic partner, delivering a product that is ready for use or integration. At this stage, there is a precise and certified quality control.In questa fase c’è un controllo qualità puntale e certificato.

Welding

Verona Lamiere is able to offer customised welding solutions with highly qualified and certified operators, adapting to the specific needs of customers and the type of parts to be produced. The techniques used include TIG, MIG, MAG and Laser welding.

Specific treatments

Through our subsidiary HVL Color, we offer a complete range of surface treatments to ensure high-quality, durable and resistant finishes, customized to the specific needs of our customers. Some examples are sandblasting, painting, and silkscreen printing.