Technology

TECHNOLOGIES CONTINUALLY EVOLVING

Success lies in having precisely those skills required at that moment.

Henry Ford

The main strength of the company has always been its great operational adaptability, in collaboration with state-of-the-art technology. This facilitates sophisticated processing at small, medium and large scales of production. All of this is always accompanied by a vision aimed at growth and investment.

The company has been able to develop an organization capable of operating, not only by making the most out of its technological systems, but also the specific skills acquired over time by individual operators. This is done using lean production logic and rigorous quality control systems.

Stainless steel and Aluminium welding workstations

Spot welding and assembling workstations

Punching machines

Robot assisted bending isles

Laser machines

Bending press brakes

Combi machines

Panel benders

Carbon steel welding workstations

Punching machines

Machining centers

Stamping and machining workstations

6 million euros in investments and 19 new systems installed in the last 3 years

DESIGN ANALYSIS

Each product, before being manufactured, requires an in-depth technical-economic study in order to guarantee the definition of the bill of materials and the optimal production cycle.

Once this first phase has been completed, the drawings and CAD/CAM programs, which are the basis for the production of the parts using CNC machines, are produced.

In this phase of industrialisation, the Project Manager and the Technical Leader are tasked with the responsibility of guaranteeing the customer a sample that complies with all the required specifications.

A specific Technical Review is also carried out with managers for each of the different technologies in order to anticipate any potential major issues during the production process.

The entire production cycle is then managed, both in terms of programming and progress, via dedicated software. The level of professionalism and amount of attention that the company pays to the training of its staff is critical in order to facilitate efficient management of production and management, which are growing in complexity, as determined by the market.

QUALITY CONTROL

The quality of each product is guaranteed by a certified quality control assessment at every step of the processing cycle and is also guaranteed by the excellence of raw materials used. To this end, our company uses selected suppliers who are able to guarantee high standards of quality.

Further verification processes are involved during the approval phase and throughout the entire production cycle, based on the best technologies available on the market.

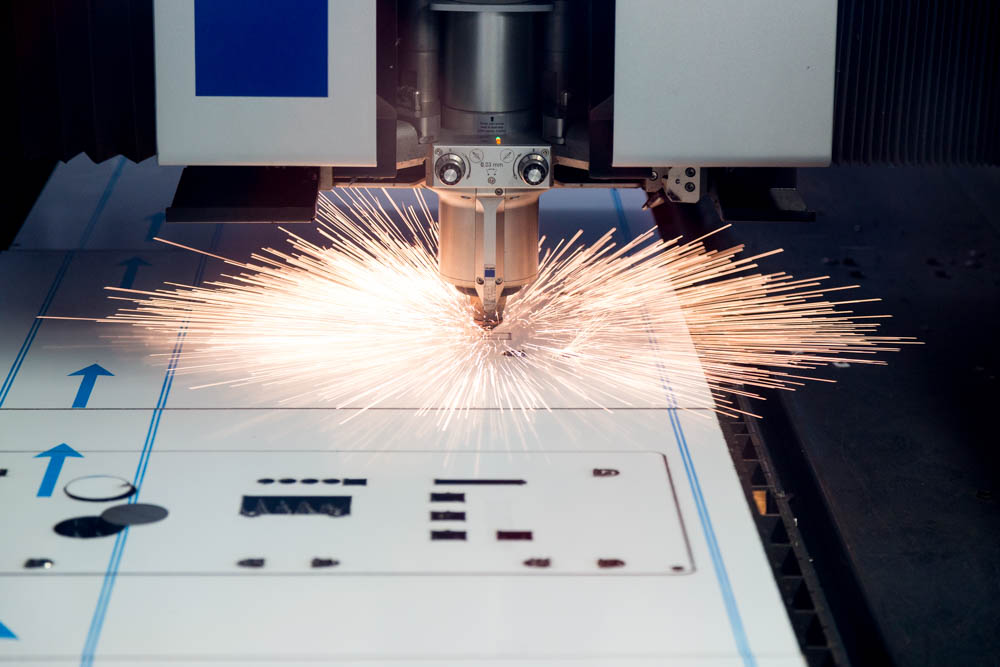

CUTTING DEPARTMENT

7 Laser plants

- Both CO2 and fiber technologies

- Power up to 6000 W

- Working area up to 4000 x 2000 mm

- Several brand strategy for getting the best performances on each application (Trumpf Homberger, Salvagnini, Penta, Finn Power)

3 Punching plants

- Electrical and hydraulic technologies

- Working area up to 3000×1520 mm

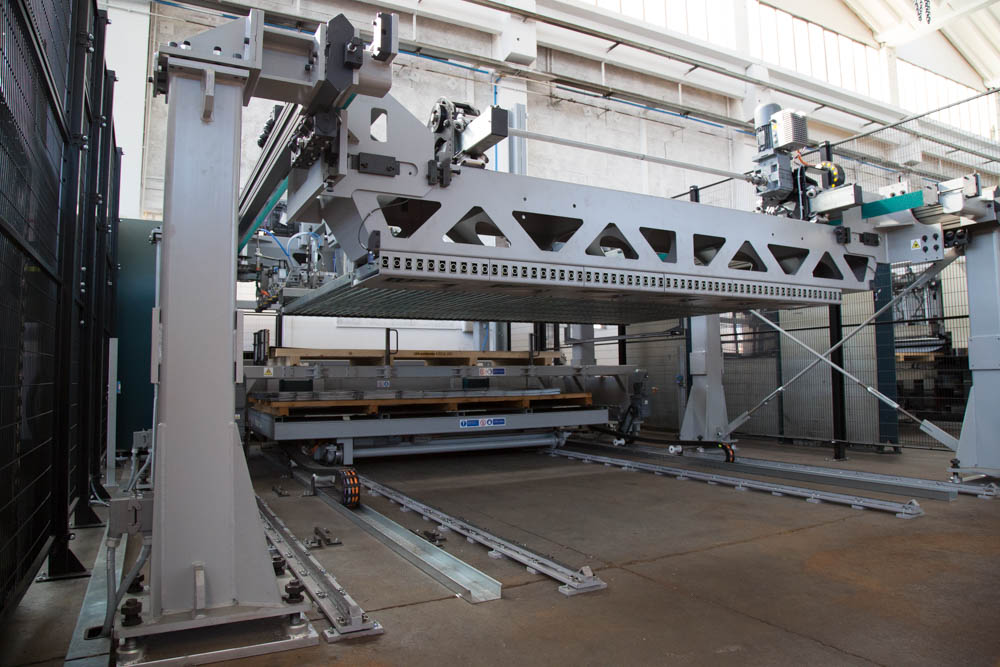

- Robotised load and download process

- Integrated shearing machine

2 Combi plants

- Both CO2 and fiber technologies + punching

- Electrical and hydraulic technologies

- Working area up to 3000×1500 mm

- Robotised load and download process

BENDING DEPARTMENT

3 Panel benders

- Salvagnini systems

- Working area up to diag 3000 mm

6 Robot assisted bending isles

- Starmatik (antropomorphic) and Antil (cartesian) systems

- Press brakes power up to 200 ton

- Working length up to 4,7 meters

15 Bending press brakes

- CNC mechanical and hydraulic technology

- Press brakes power up to 300 ton

- Working length up to 4 meters

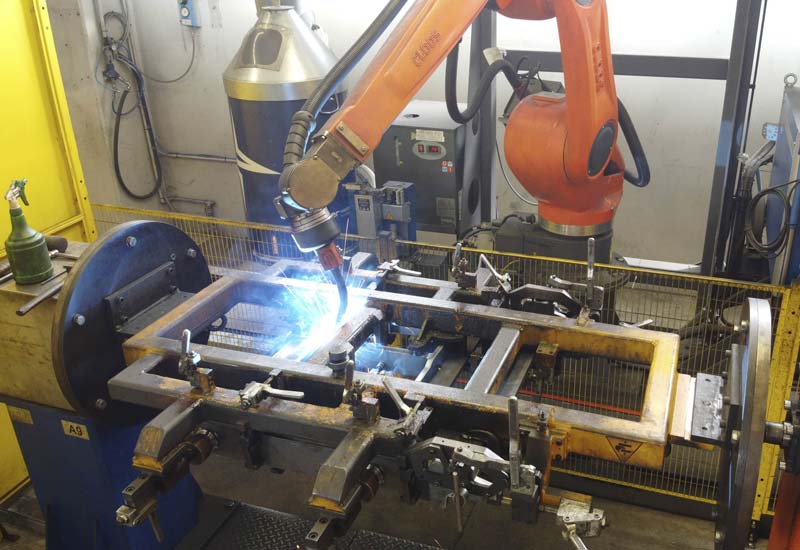

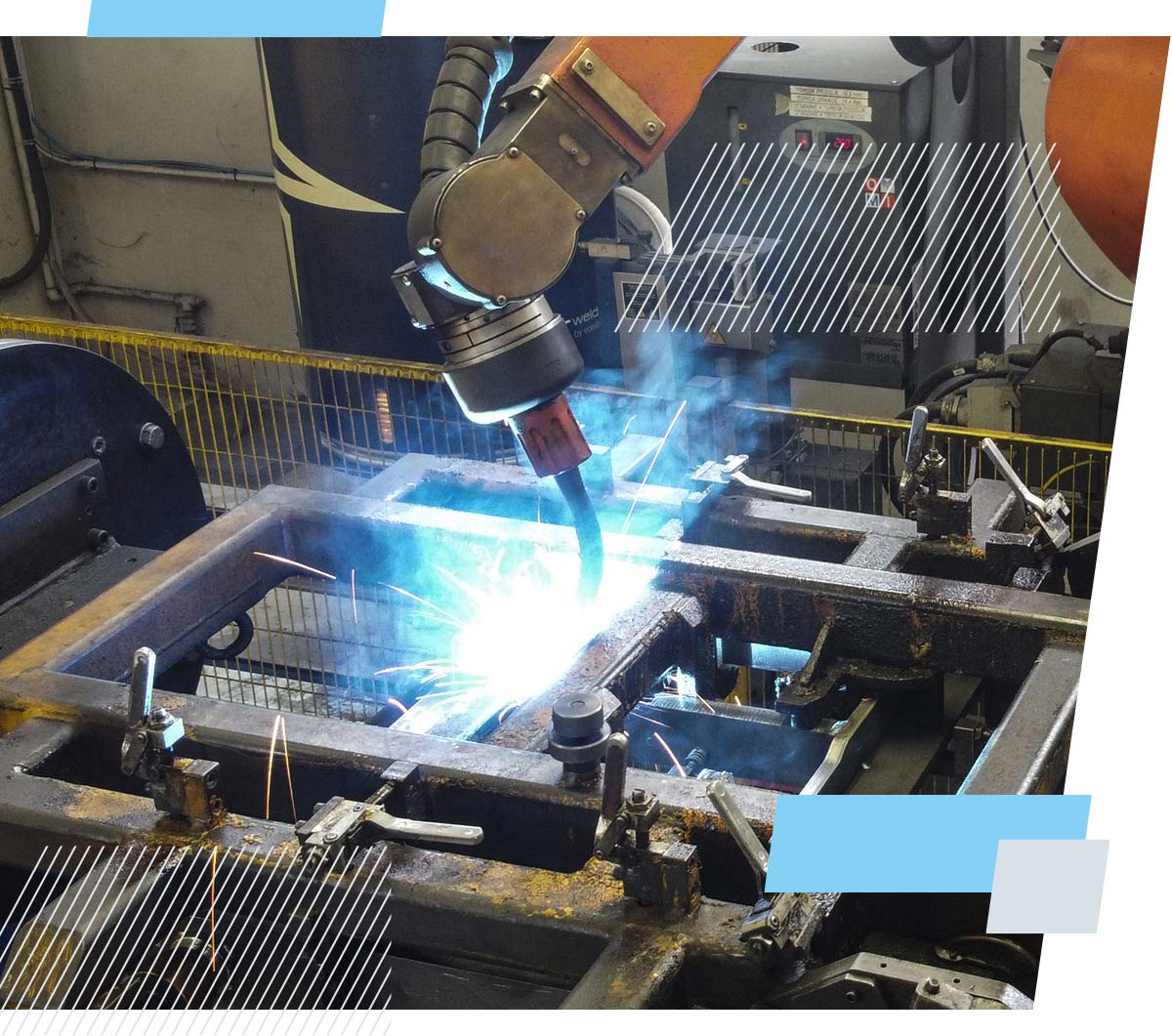

WELDING AND ASSEMBLY DEPARTMENT

20 Stainless steel and Aluminium welding

- 1.000 sqm

- 20 welders and operators

- 4 robotised TIG/MIG stations (Motoman, Fanuc)

- 12 manual stations

12 Carbon steel welding

- 1.000 sqm

- 12 welders and operators

- 5 manual stations

- 3 robotised MAG stations (Cloos, OTC)

20 Spot welding and Assembling

- 1.000 sqm

- 20 welders and operators

- 1 robotized spot-welding station

- 15 manual stations

3D measurement

- Full operational stations

- Digital comparison vs drawing

- Automatic reporting

STAMPING AND MACHINING DEPARTMENT

17 Stamping

- 12 operators

- 3 PEMSERT machines

- 10 mechanical presses

- power up to 500 ton

- 4 hydraulic presses

- power up to 200 ton

5 Machining

- 8 operators

- 3 machining centers

- 3+1 Axis

- Working area up to 1500 mm x 500 mm

- 2 machining centers

- 3 Axis

- Working area up to 4000 mm x 2500 mm

PAINTING AND FINISHING DEPARTMENT

Painting department

- 30 operators

- 2 automatic powder coating lines with Basf Oxilan nano surface peatreatment

- 1 semi automatic powder coating line

- 1 manual liquid coating line

Assembly department

- 15 operators

- Final assembly, mounting and kitting operations

LOGISTIC

At the end of each processing stage, the material is identified and is then swiftly allocated to a job. Positioning is automatically reported to the central information system via wireless technology.

Each material that has reached the end of production is carefully packed by automated systems on pallets and identified by barcode for easier traceability and as part of the recognition necessary in this process.

In a special warehouse, semi-finished and finished products are stored ready for subsequent shipment and for the management of kanban, call-off material.

The delivery takes place through a punctual and safe transport service, either by our means of transport or alternatively by the Customer’s support courier.